ASA Bambu Lab US

Par un écrivain mystérieux

Description

Bambu ASA Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions. Extraordinary Weather & UV Resistance Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes. Tough and Durable Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength. Better Temperature Resistance Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C. Frequently Asked Questions 1. What's the difference between ABS and ASA? ABS ASA Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene -

Bambu ASA Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions. Extraordinary Weather & UV Resistance Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes. Tough and Durable Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength. Better Temperature Resistance Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C. Frequently Asked Questions 1. What's the difference between ABS and ASA? ABS ASA Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance. ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS. 2. What is the difference applications between ABS and ASA? ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications. 3. What are the similarities between ABS and ASA? In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models. Parameters Comparison Learn more different filaments comparison on Bambu Filament Guide >> ABS ASA PC Price / kg $27.99 $29.99 $39.99 Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate Polycarbonate Hotend Compatibility All Size/Material Build Plate Compatibility Engineering Plate, High Temperature Plate, Textuerd PEI Plate AMS Compatibility Yes Yes Yes Glue Bambu Liqud Glue/Glue Stick Bambu Liqud Glue/Glue Stick Glue Stick Dry Out Before Use Recommended Recommended Required Odor During Printing Pungent odor Relatively lighter pungent odor Light phenol-flavored odor Toughness (Impact Strength - XY) 39.3 kJ/m² 41.0 kJ/m² 34.8 kJ/m² Strength (Bending Strength - XY) 62 MPa 65 MPa 108 MPa Stiffness (Bending Modulus - XY) 1880 MPa 1920 MPa 2310 MPa Layer Adhesion (Impact Strength - Z) 7.4 kJ/m² 4.9 kJ/m² 9.0 kJ/m² Heat Resistant(HDT, 0.45 MPa) 87 ℃ 100 ℃ 117 ℃ Saturated Water Absorption Rate / % (25 °C,55% RH) 0.65% 0.45% 0.25% Accessory Compatibility Recommended Not Recommended Build Plate Engineering Plate, High Temperature Plate or Textured PEI Plate Cool Plate Hotend All Size / Material / Glue Bambu Liquid Glue Glue Stick / ASA Hex Code Table Color Hex Code Display White #FFFAF2 Gray #8A949E Red #E02928 Green #00A6A0 Blue #2140B4 Black #000000 RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 80 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, with Desiccant) Nozzle Temperature 240 - 270 °C Bed Temperature (with Glue) 80 - 100 °C Printing Speed < 250 mm/s Physical Properties Density 1.05 g/cm³ Vicat Softening Temperature 106 °C Heat Deflection Temperature 100 °C Melting Temperature 210 °C Melt Index 7.0 ± 0.8 g/10 min Mechanical Properties Tensile Strength 37 ± 3 MPa Breaking Elongation Rate 9.2 ± 1.4 % Bending Modulus 1920 ± 130 MPa Bending Strength 65 ± 5 MPa Impact Strength 41.0 ± 2.3 kJ/m² Downloads Filament TDS Filament MSDS Filament RoHS Printing Tips • Pungent and unpleasant odors may be released during printing. Make • Drying conditions: 80 ℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI. • ASA is prone to warping when printing large size and/or high infill density model. To avoid warping: 1) Not recommemded to print too large size and/or high infill density models. 2) Use enclosure printers and ensure the build plate is properly glued before printing. 3) Set lower printing speed and higher heatbed temperature. For more details please refer to: Common print quality problems and solutions on WIKI. What's in the Box? Filament with Spool*1 & Desiccant*1 Filament Label*1 Package*1

Bambu ASA Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions. Extraordinary Weather & UV Resistance Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes. Tough and Durable Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength. Better Temperature Resistance Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C. Frequently Asked Questions 1. What's the difference between ABS and ASA? ABS ASA Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance. ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS. 2. What is the difference applications between ABS and ASA? ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications. 3. What are the similarities between ABS and ASA? In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models. Parameters Comparison Learn more different filaments comparison on Bambu Filament Guide >> ABS ASA PC Price / kg $27.99 $29.99 $39.99 Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate Polycarbonate Hotend Compatibility All Size/Material Build Plate Compatibility Engineering Plate, High Temperature Plate, Textuerd PEI Plate AMS Compatibility Yes Yes Yes Glue Bambu Liqud Glue/Glue Stick Bambu Liqud Glue/Glue Stick Glue Stick Dry Out Before Use Recommended Recommended Required Odor During Printing Pungent odor Relatively lighter pungent odor Light phenol-flavored odor Toughness (Impact Strength - XY) 39.3 kJ/m² 41.0 kJ/m² 34.8 kJ/m² Strength (Bending Strength - XY) 62 MPa 65 MPa 108 MPa Stiffness (Bending Modulus - XY) 1880 MPa 1920 MPa 2310 MPa Layer Adhesion (Impact Strength - Z) 7.4 kJ/m² 4.9 kJ/m² 9.0 kJ/m² Heat Resistant(HDT, 0.45 MPa) 87 ℃ 100 ℃ 117 ℃ Saturated Water Absorption Rate / % (25 °C,55% RH) 0.65% 0.45% 0.25% Accessory Compatibility Recommended Not Recommended Build Plate Engineering Plate, High Temperature Plate or Textured PEI Plate Cool Plate Hotend All Size / Material / Glue Bambu Liquid Glue Glue Stick / ASA Hex Code Table Color Hex Code Display White #FFFAF2 Gray #8A949E Red #E02928 Green #00A6A0 Blue #2140B4 Black #000000 RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 80 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, with Desiccant) Nozzle Temperature 240 - 270 °C Bed Temperature (with Glue) 80 - 100 °C Printing Speed < 250 mm/s Physical Properties Density 1.05 g/cm³ Vicat Softening Temperature 106 °C Heat Deflection Temperature 100 °C Melting Temperature 210 °C Melt Index 7.0 ± 0.8 g/10 min Mechanical Properties Tensile Strength 37 ± 3 MPa Breaking Elongation Rate 9.2 ± 1.4 % Bending Modulus 1920 ± 130 MPa Bending Strength 65 ± 5 MPa Impact Strength 41.0 ± 2.3 kJ/m² Downloads Filament TDS Filament MSDS Filament RoHS Printing Tips • Pungent and unpleasant odors may be released during printing. Make • Drying conditions: 80 ℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI. • ASA is prone to warping when printing large size and/or high infill density model. To avoid warping: 1) Not recommemded to print too large size and/or high infill density models. 2) Use enclosure printers and ensure the build plate is properly glued before printing. 3) Set lower printing speed and higher heatbed temperature. For more details please refer to: Common print quality problems and solutions on WIKI. What's in the Box? Filament with Spool*1 & Desiccant*1 Filament Label*1 Package*1

Bambu ASA Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions. Extraordinary Weather & UV Resistance Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes. Tough and Durable Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength. Better Temperature Resistance Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C. Frequently Asked Questions 1. What's the difference between ABS and ASA? ABS ASA Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance. ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS. 2. What is the difference applications between ABS and ASA? ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications. 3. What are the similarities between ABS and ASA? In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models. Parameters Comparison Learn more different filaments comparison on Bambu Filament Guide >> ABS ASA PC Price / kg $27.99 $29.99 $39.99 Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate Polycarbonate Hotend Compatibility All Size/Material Build Plate Compatibility Engineering Plate, High Temperature Plate, Textuerd PEI Plate AMS Compatibility Yes Yes Yes Glue Bambu Liqud Glue/Glue Stick Bambu Liqud Glue/Glue Stick Glue Stick Dry Out Before Use Recommended Recommended Required Odor During Printing Pungent odor Relatively lighter pungent odor Light phenol-flavored odor Toughness (Impact Strength - XY) 39.3 kJ/m² 41.0 kJ/m² 34.8 kJ/m² Strength (Bending Strength - XY) 62 MPa 65 MPa 108 MPa Stiffness (Bending Modulus - XY) 1880 MPa 1920 MPa 2310 MPa Layer Adhesion (Impact Strength - Z) 7.4 kJ/m² 4.9 kJ/m² 9.0 kJ/m² Heat Resistant(HDT, 0.45 MPa) 87 ℃ 100 ℃ 117 ℃ Saturated Water Absorption Rate / % (25 °C,55% RH) 0.65% 0.45% 0.25% Accessory Compatibility Recommended Not Recommended Build Plate Engineering Plate, High Temperature Plate or Textured PEI Plate Cool Plate Hotend All Size / Material / Glue Bambu Liquid Glue Glue Stick / ASA Hex Code Table Color Hex Code Display White #FFFAF2 Gray #8A949E Red #E02928 Green #00A6A0 Blue #2140B4 Black #000000 RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 80 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, with Desiccant) Nozzle Temperature 240 - 270 °C Bed Temperature (with Glue) 80 - 100 °C Printing Speed < 250 mm/s Physical Properties Density 1.05 g/cm³ Vicat Softening Temperature 106 °C Heat Deflection Temperature 100 °C Melting Temperature 210 °C Melt Index 7.0 ± 0.8 g/10 min Mechanical Properties Tensile Strength 37 ± 3 MPa Breaking Elongation Rate 9.2 ± 1.4 % Bending Modulus 1920 ± 130 MPa Bending Strength 65 ± 5 MPa Impact Strength 41.0 ± 2.3 kJ/m² Downloads Filament TDS Filament MSDS Filament RoHS Printing Tips • Pungent and unpleasant odors may be released during printing. Make • Drying conditions: 80 ℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI. • ASA is prone to warping when printing large size and/or high infill density model. To avoid warping: 1) Not recommemded to print too large size and/or high infill density models. 2) Use enclosure printers and ensure the build plate is properly glued before printing. 3) Set lower printing speed and higher heatbed temperature. For more details please refer to: Common print quality problems and solutions on WIKI. What's in the Box? Filament with Spool*1 & Desiccant*1 Filament Label*1 Package*1

Bambu ASA Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions. Extraordinary Weather & UV Resistance Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes. Tough and Durable Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength. Better Temperature Resistance Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C. Frequently Asked Questions 1. What's the difference between ABS and ASA? ABS ASA Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance. ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS. 2. What is the difference applications between ABS and ASA? ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications. 3. What are the similarities between ABS and ASA? In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models. Parameters Comparison Learn more different filaments comparison on Bambu Filament Guide >> ABS ASA PC Price / kg $27.99 $29.99 $39.99 Composition acrylonitrile - butadiene - styrene acrylonitrile - styrene - acrylate Polycarbonate Hotend Compatibility All Size/Material Build Plate Compatibility Engineering Plate, High Temperature Plate, Textuerd PEI Plate AMS Compatibility Yes Yes Yes Glue Bambu Liqud Glue/Glue Stick Bambu Liqud Glue/Glue Stick Glue Stick Dry Out Before Use Recommended Recommended Required Odor During Printing Pungent odor Relatively lighter pungent odor Light phenol-flavored odor Toughness (Impact Strength - XY) 39.3 kJ/m² 41.0 kJ/m² 34.8 kJ/m² Strength (Bending Strength - XY) 62 MPa 65 MPa 108 MPa Stiffness (Bending Modulus - XY) 1880 MPa 1920 MPa 2310 MPa Layer Adhesion (Impact Strength - Z) 7.4 kJ/m² 4.9 kJ/m² 9.0 kJ/m² Heat Resistant(HDT, 0.45 MPa) 87 ℃ 100 ℃ 117 ℃ Saturated Water Absorption Rate / % (25 °C,55% RH) 0.65% 0.45% 0.25% Accessory Compatibility Recommended Not Recommended Build Plate Engineering Plate, High Temperature Plate or Textured PEI Plate Cool Plate Hotend All Size / Material / Glue Bambu Liquid Glue Glue Stick / ASA Hex Code Table Color Hex Code Display White #FFFAF2 Gray #8A949E Red #E02928 Green #00A6A0 Blue #2140B4 Black #000000 RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 80 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, with Desiccant) Nozzle Temperature 240 - 270 °C Bed Temperature (with Glue) 80 - 100 °C Printing Speed < 250 mm/s Physical Properties Density 1.05 g/cm³ Vicat Softening Temperature 106 °C Heat Deflection Temperature 100 °C Melting Temperature 210 °C Melt Index 7.0 ± 0.8 g/10 min Mechanical Properties Tensile Strength 37 ± 3 MPa Breaking Elongation Rate 9.2 ± 1.4 % Bending Modulus 1920 ± 130 MPa Bending Strength 65 ± 5 MPa Impact Strength 41.0 ± 2.3 kJ/m² Downloads Filament TDS Filament MSDS Filament RoHS Printing Tips • Pungent and unpleasant odors may be released during printing. Make • Drying conditions: 80 ℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI. • ASA is prone to warping when printing large size and/or high infill density model. To avoid warping: 1) Not recommemded to print too large size and/or high infill density models. 2) Use enclosure printers and ensure the build plate is properly glued before printing. 3) Set lower printing speed and higher heatbed temperature. For more details please refer to: Common print quality problems and solutions on WIKI. What's in the Box? Filament with Spool*1 & Desiccant*1 Filament Label*1 Package*1

Shop 3D printers, filmaments and accessories - Bambu Lab US store

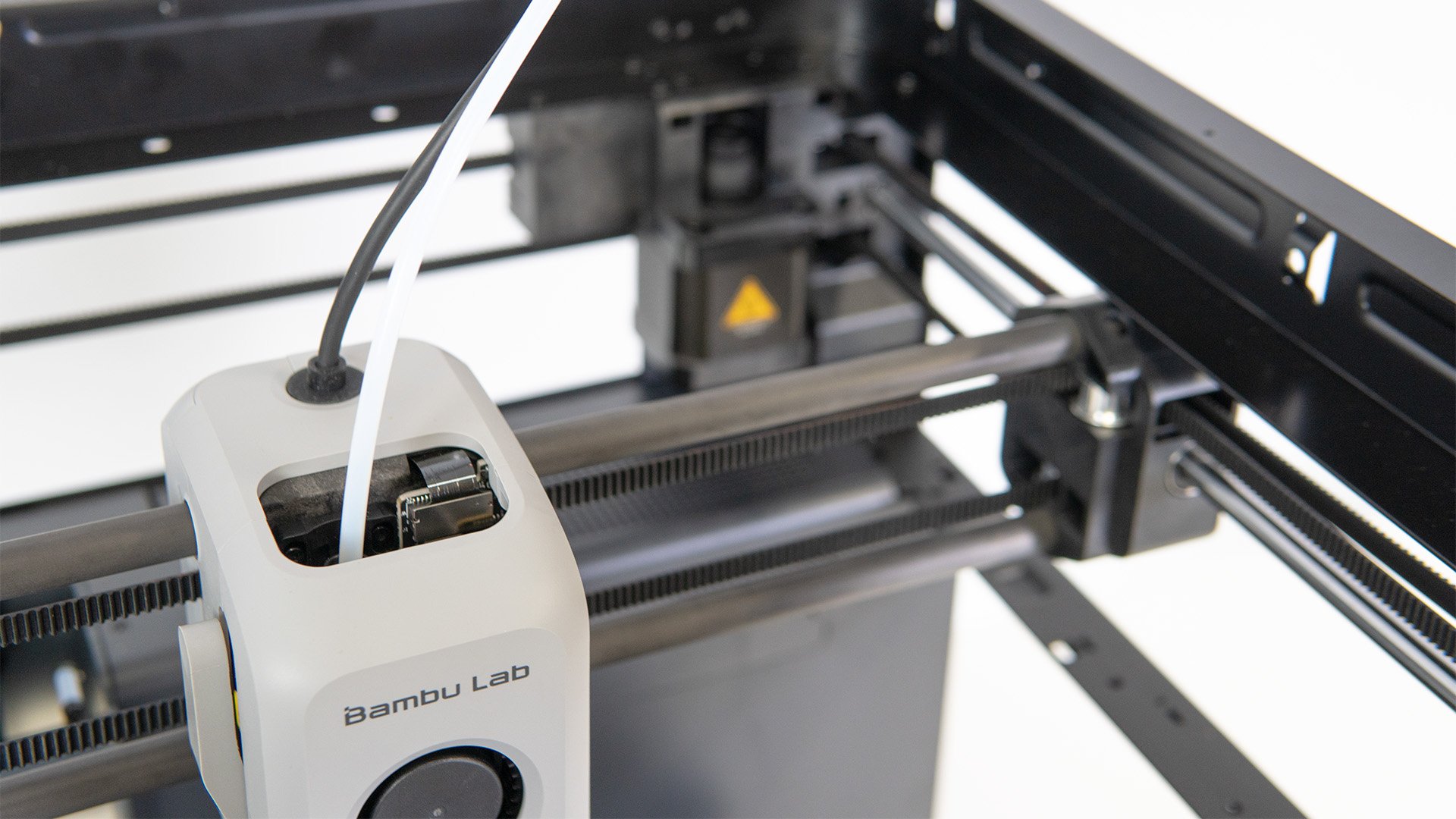

Bambu Lab AMS is an intelligent system that communicates with the toolhead to guarantee smooth feeding and automatic mid-print filament switching. It can detect the tension on filament and actively adjust the feeding pace. With RFID technology, Bambu Lab AMS identifies filament loaded inside and automatically configures the most appropriate print settings.

Bambu Lab AMS - Automatic Material System

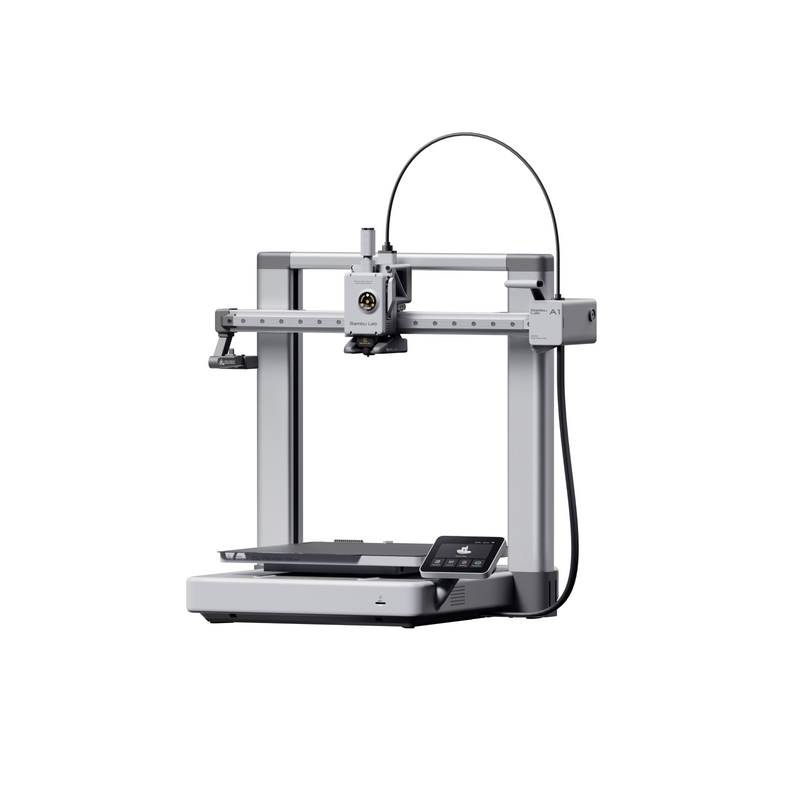

Bambu Lab A1 Combo, Multi-Color Printing, Full-auto Calibration, Active Flow Rate Compensation, 1-Clip Quick Swap Nozzle, Active Motor Noise

Bambu Lab A1 3D Printer

Bambu Lab X1E 3D Printer - Engineering Bundle

Bambu Lab X1-Carbon Combo

Bambu Lab X1 Carbon (AMS) Review: Fresh Thinking, No Tinkerin

The all-new AMS lite is elegant and reliable, making multi-color 3D printing accessible to everyone. The A1 mini comes to you pre-assembled, pre-squared, and pre-tuned with precision. It only takes about 20 minutes to set up for your first print. A1 mini handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically. A1 mini probes the bed with the nozzle to measure the absolute z-offset.

Bambu Lab A1 Mini 3D Printer; 2.4 Color IPS Touch Screen; Automatic Leveling

ASA Bambu Lab US

Bambu Lab P1P Review: Shaking Things Up

depuis

par adulte (le prix varie selon la taille du groupe)